Origin

Tea plant (camellia sinensis)

The word Tea comes from the Chinese dialect Amoy “t'e” and it is pronounced “tay”.

In the Cantonese dialect it was called “ch'a” and it is pronounced “cha”. With this denomination it is known in Japan, India, Persia and Russia. While in Europe the word “t'e” was adopted.

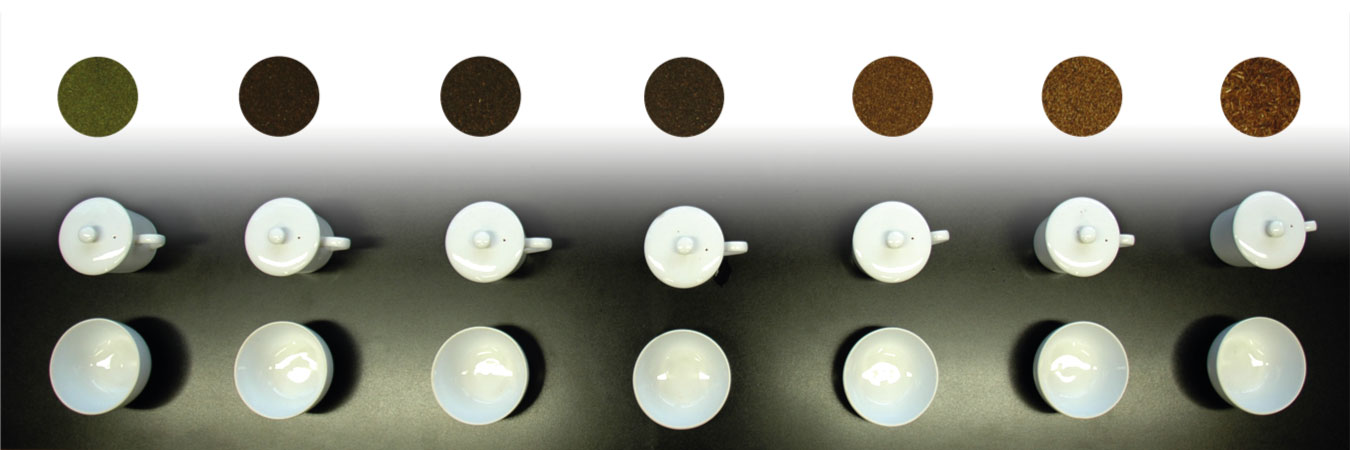

The leaves of this plant, with such special characteristics, constitute the raw material to produce tea. Tender buds of camellia sinensis constitute the basic raw material. These change physically and chemically during the process, obtaining a 22% of dry mass.

The harvest period is from October to May, in good weather conditions, with regular rains, high humidity and appropriate temperature. It requires acid, permeable, deep soils with abundant organic matter.

Our biggest production is of “Black Tea” and we also produce the varieties “Steamed Green Tea” and “Pan-Fired Green Tea”.